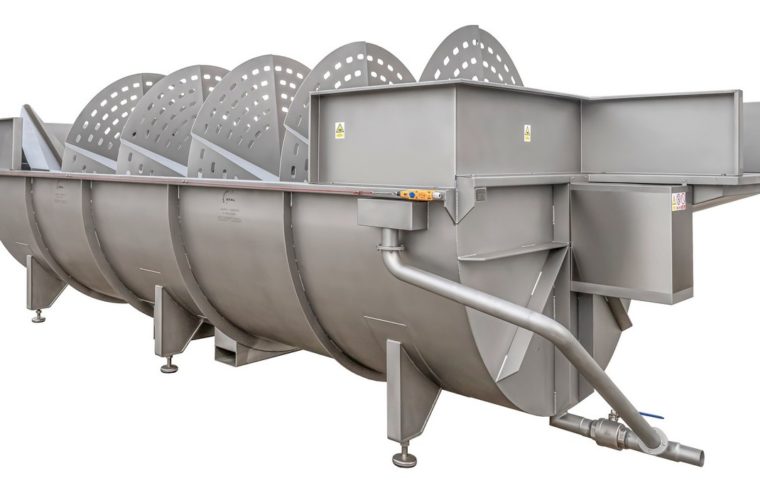

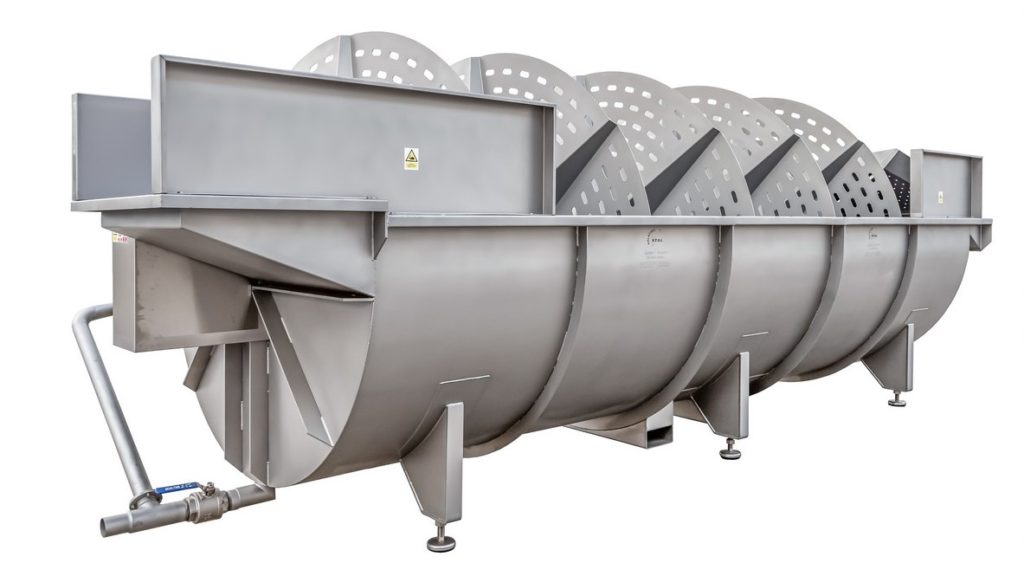

The giblet spin chiller is designed to reduce the temperature of hearts, livers, gizzards, necks and feet.

OPERATION

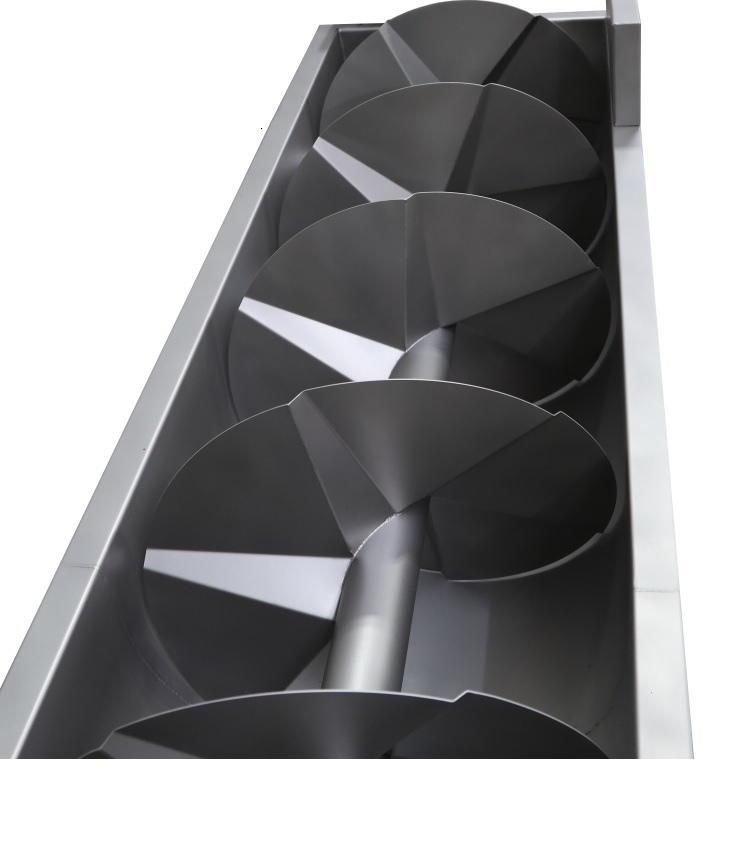

The parts to be chilled, depending on the location of the production line and the position of the chiller, fall directly from the line into the chiller (e.g. feet from the unloader or offal from a conveyor belt placed by the evisceration stand) or are manually fed into the chiller. Then, using a screw, they are moved to the end of the tank where they are automatically ejected to a prepared tank, a gutter, a conveyor belt or any other way of collection provided for in the technological design. The length and width of the offal chiller is determined according to the capacity and size of the pieces to be chilled. Ice water is used for cooling. When tap water is used, crushed ice or scaly ice must be added during the chilling operation.

ADVANTAGES

– The most effective way to lower the temperature while maintaining all the qualities of the product

TECHNICAL SPECIFICATION |

||||

|