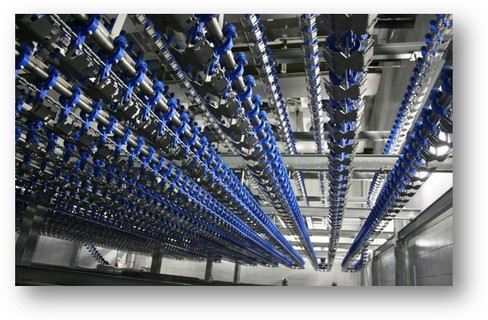

Designed to transport the product at all stages of the technological process.

In modern poultry processing, the efficiency of each operational stage can significantly influence overall productivity, profitability, and product quality. One critical factor in this efficiency equation is the careful and consistent movement of birds through every phase of the process, from the moment they enter the facility to their preparation as finished products.

Szlachet-Stal’s overhead conveyors excel at providing a streamlined, automated transport solution, ensuring that each bird moves smoothly along the production line.

Our overhead conveyors are engineered with durability, precision, and adaptability in mind. Built from high-quality materials designed to withstand demanding conditions, these systems facilitate continuous product flow, reduce manual handling, and minimize downtime.

Suspending the product above floor level, overhead conveyors help maintain a clean, obstacle-free workspace. This not only improves on-site hygiene but also optimizes staff movement, as valuable floor space remains clear and accessible. The elevated positioning of the system keeps products at a convenient working height, enabling better ergonomic conditions and reducing employee fatigue, which ultimately leads to improved overall performance and productivity.

Integrating Rehangers from Killing Line to Evisceration Line

A critical link in achieving seamless product flow is the transition between different processing stages. One particularly intricate stage change takes place when carcasses move from the killing line to the evisceration line.

This is where Szlachet-Stal’s dedicated rehangers from killing line to evisceration line prove indispensable. These specialized mechanisms ensure that each carcass is securely transferred between the two critical phases of poultry processing, maintaining a continuous flow without compromising quality or safety.

The rehanging process can be challenging without the right tools, as it requires precise handling to avoid damaging the product and to maintain strict hygiene standards. Szlachet-Stal’s rehangers are designed with high-precision components and adjustable settings to accommodate different product sizes and operational requirements.

Automating this delicate transition, producers can reduce reliance on manual labor, thus minimizing the risk of human error and product contamination. This not only improves product consistency and quality but also allows staff to focus on tasks that require human oversight, improving overall workflow efficiency.

Enhancing Food Safety and Product Quality

Every stage of poultry processing is guided by stringent regulations and meticulous standards. Overhead conveyors and integrated rehangers from killing line to evisceration line contribute significantly to maintaining compliance and ensuring that the final products meet or exceed industry benchmarks.

Suspended transport systems make it easier to monitor product flow, spot potential issues quickly, and address them before they escalate. The controlled, automated handover between the killing and evisceration lines reduces the potential for cross-contamination, ensuring that the entire operation consistently delivers safe, high-quality poultry products to the market.

By integrating these advanced systems into your production line, you create a predictable and traceable workflow that is easily auditable.

Such transparency fosters consumer trust and supports brand reputation in a competitive marketplace where customers demand both safety and excellence.

These improved operational standards can translate to stronger long-term business results, as high-quality products lead to repeat business, positive reviews, and a more robust market presence.

Long-Term Performance and Support

When you invest in Szlachet-Stal’s overhead conveyors and specialized rehangers, you gain access not only to cutting-edge equipment but also to a team of experts dedicated to your success.

From initial installation and configuration to ongoing maintenance and support, we work closely with our clients to ensure that every solution delivers optimal performance over the long term.

Our specialists help fine-tune system parameters, suggest improvements, and provide training that empowers your team to achieve peak efficiency on a daily basis.

As your operation grows and market demands change, our equipment is designed to scale alongside you. With modular components and upgrade paths, our overhead conveyors and rehangers from killing line to evisceration line can adapt to increased throughput, shifting product mixes, or new regulatory conditions.

This flexibility positions your facility for sustainable growth, allowing you to stay competitive and responsive to evolving industry trends.

Integrating overhead conveyors and automated rehangers ensures that you maintain a forward-thinking approach to poultry processing. With Szlachet-Stal’s expertise and advanced solutions at your disposal, you can confidently bring consistent, premium poultry products to the marketplace—setting new standards for efficiency, quality, and customer satisfaction.

OPERATION

The conveyor can be freely configured so that it is fully adapted to the investor’s needs. The use of appropriate size shackles allows for the transport of all types of poultry and all kinds of divided elements. The standard conveyor is based on a load chain with a division of 1 ”. It can be made in a stainless or galvanized version. The conveyor includes: drive, tensioner, 90o and 180o bends, straight tracks, vertical bends, chain carts, shackles, joints. The chain conveyor is suspended from the supporting structure, additionally made according to the contractor’s guidelines.

ADVANTAGES

– Fully customizable

– Many types of shackles