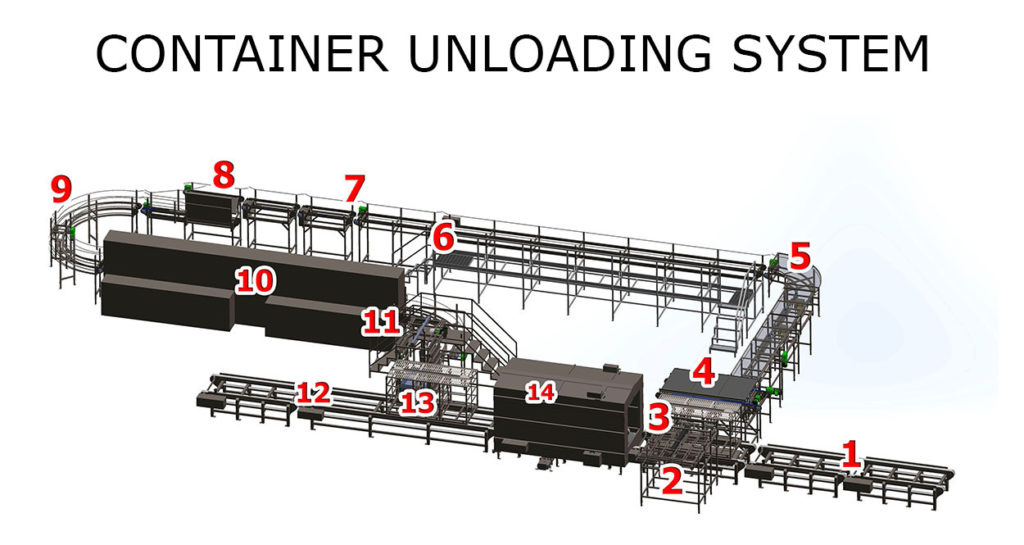

1 Container conveyor

2 De-stacker

3 Scissor-lift

4 Unloading table

5 Chain conveyor for transport of crates

6 Catwalk for hanging poultry

7 Chain conveyor for transport of crates

8 Crate rotating system

9 Chain conveyor for transport of crates

10 Crate washer

11 Stacker

12 Container conveyor

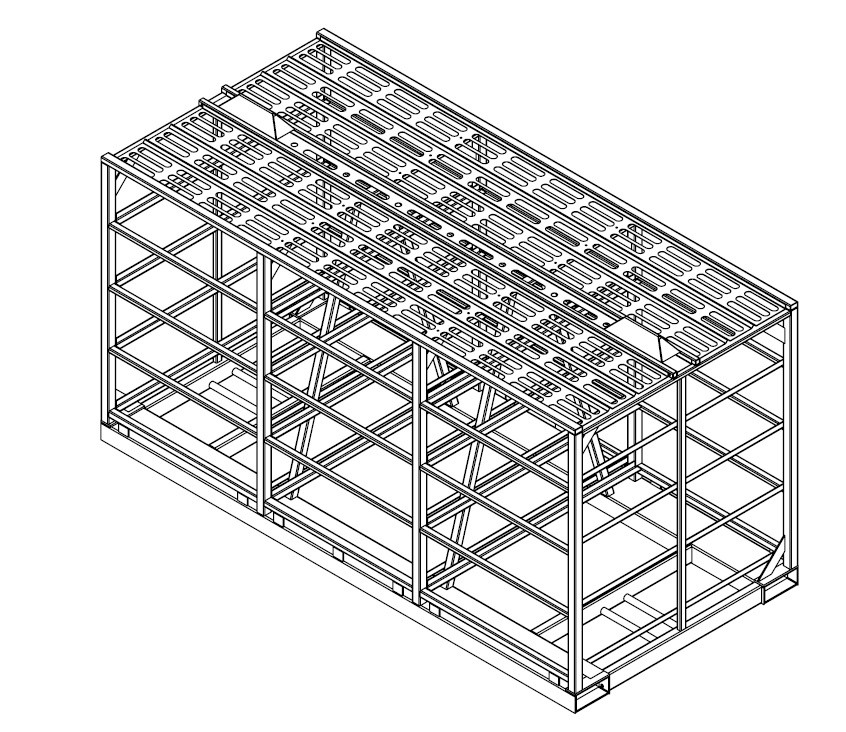

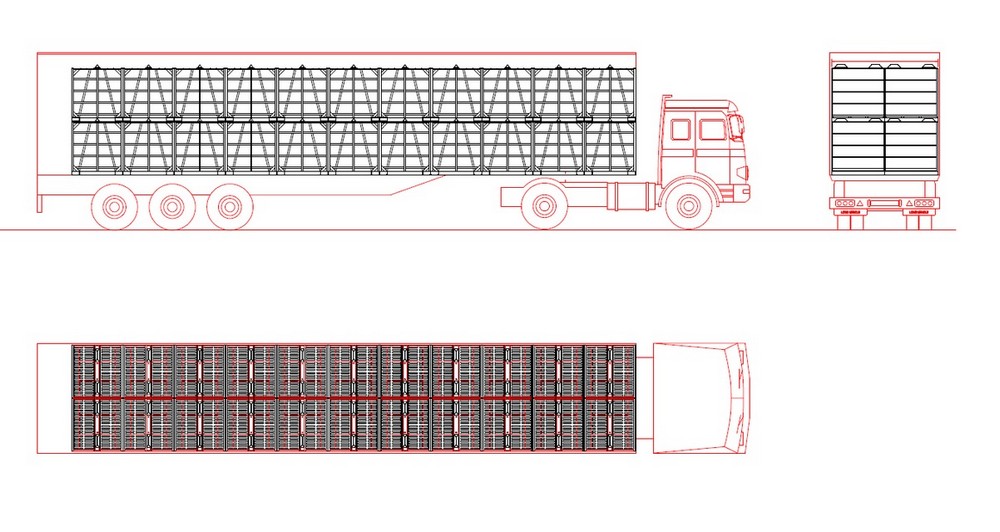

13 4-level container

14 Container washer

ADVANTAGES

-Excluding the live poultry hanging stage, the live unloading process is fully automated. The conventional unloading stage is physically demanding for the workers and the system is able to fully fulfil this task.

– A state-of-the-art system for transporting live birds that ensures their safety and greatly improves slaughterhouse operations.

– Full adjustment of the system to the Investor’s needs and expectations, such as slaughter capacity and available space.