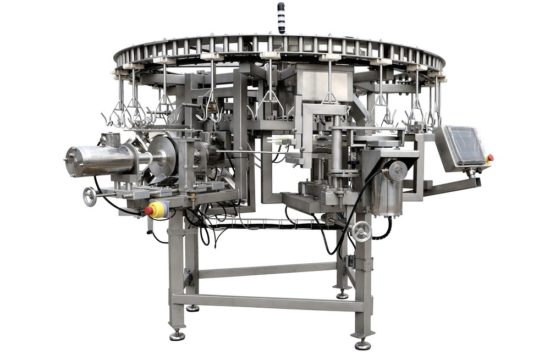

We understand that delivering high-quality poultry products begins with precise grading solutions. Our poultry grading machines are engineered to help producers sort, classify, and evaluate every piece with remarkable accuracy and efficiency.

By integrating advanced sensors, adjustable control panels, and innovative software, each machine operates smoothly and consistently, ensuring that each cut of poultry meets the desired criteria. This meticulous approach to grading not only optimizes the overall quality of the output but also reduces instances of underutilized inventory, thereby maximizing the value of each batch.

Our poultry grading machines not only streamline production but also help maintain end-consumer satisfaction, reinforcing brand loyalty and positive market recognition.

Precision in Poultry Cut-Up for Maximum Yield

Beyond grading, the process of poultry cut-up is a critical step that demands both precision and speed. Szlachet-Stal’s cutting solutions incorporate careful design, robust construction, and intelligent automation to ensure maximum yield and minimal product wastage.

During poultry cut-up, our systems deliver uniform and exact cuts, minimizing size variation and enabling the production line to consistently meet industry standards. This focus on precision helps processors achieve tighter control over portion sizes, allowing them to cater to a wide range of commercial requirements, from whole cuts and fillets to wing segments and drumsticks.

Optimal cut-up practices mean less downtime, fewer manual corrections, and streamlined workflows that ultimately drive down operational costs. As technology, consumer preferences, and regulatory requirements evolve, our poultry cut-up solutions remain flexible, scalable, and ready to adapt, securing a steady production rhythm and optimal profitability.

Optimized Poultry Packaging Machines for Freshness and Safety

Once the product has been effectively graded and cut, it must be presented and preserved in a way that appeals to customers while meeting rigorous food safety standards. Szlachet-Stal’s poultry packaging machines are engineered to balance speed, hygiene, and product integrity, ensuring that each package protects freshness, flavor, and texture.

Our packaging solutions embrace airtight sealing, modified atmosphere packaging, and robust materials capable of preserving both the taste and nutritional profile of the poultry throughout its distribution cycle.

With customizable settings and integrated safety features, these poultry packaging machines are designed to accommodate various packaging types, sizes, and materials, reinforcing brand identity and marketability. Whether you need vacuum-sealed packs for extended shelf life or more environmentally conscious solutions, our equipment can adapt, delivering optimal results no matter the scenario.

Investing in top-quality packaging solutions, producers can enhance brand appeal, prolong product life, and guarantee safe, wholesome poultry products to their customers.

A Holistic System Integration for Long-Term Growth

In an era where efficiency, productivity, and quality coalesce to determine success, our approach goes beyond delivering individual pieces of machinery. Szlachet-Stal’s holistic integration capabilities ensure that poultry grading machines, poultry cut-up stations, and poultry packaging machines work together seamlessly as part of a cohesive system.

By connecting these stages within a unified production flow, operators can track performance metrics, analyze yield data, and fine-tune processes to meet shifting market demands.

Advanced software integrations and custom controls allow decision-makers to identify inefficiencies, improve throughput, and plan ahead for expansion or new product lines. Moreover, our technical support and advisory services extend well beyond installation, offering continuous guidance, maintenance, and upgrades to keep systems at peak performance.

With Szlachet-Stal’s integrated cutting and packaging solutions, poultry processors can maintain a forward-thinking strategy, adjusting operations to stay competitive, scalable, and prepared for emerging industry trends.

The combination of modern poultry grading machines, precise poultry cut-up technology, and flexible poultry packaging machines transforms the production landscape, giving processors the confidence to deliver consistently superior products.

By partnering with Szlachet-Stal, producers gain access to technologically advanced equipment, informed consultation, and a commitment to quality that enhances every stage of the poultry processing journey. From the initial selection of equipment to long-term operational optimization, our cutting and packaging solutions support sustained growth, brand elevation, and a strong presence in a dynamic and demanding marketplace.