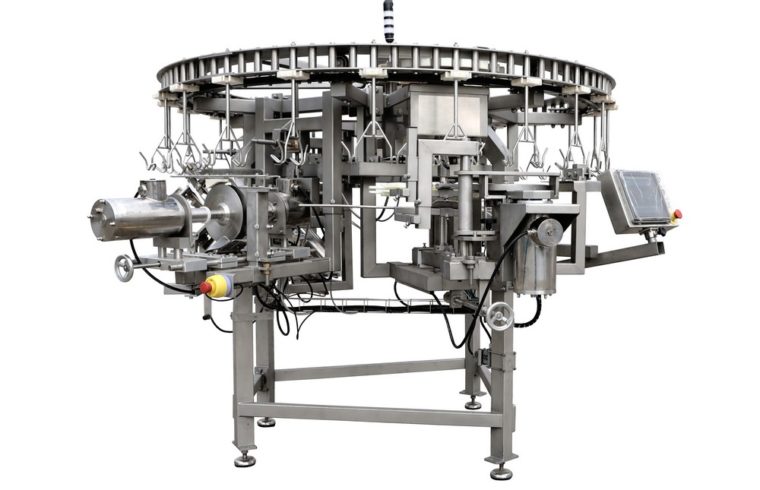

The automatic carousel cut-up line, an advanced automatic cut up system, is designed to divide the eviscerated chicken carcass into anatomical parts.

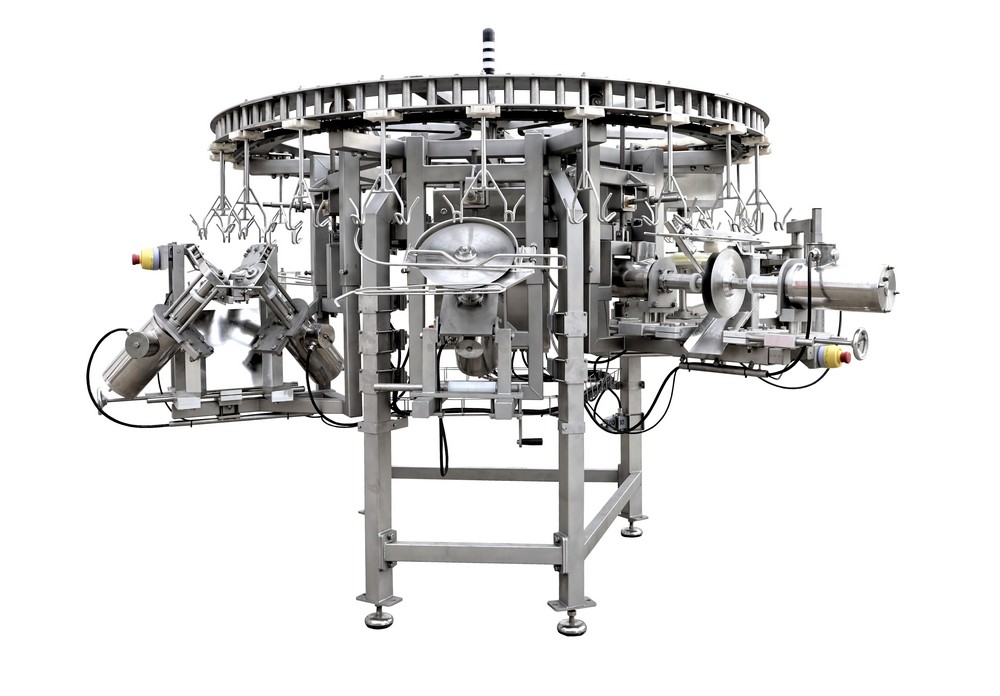

OPERATION

The automatic carousel cut-up line consists of a main frame to which the cutting modules are mounted. The control of the individual cutting modules is effected by means of an electrical cabinet integrated into the divider, ensuring a precise automatic cut. The standard design of the carousel cut-up line may include the cutting modules listed below. However, the customer may choose a limited number of modules listed, which are similar to modules for ADD cut-up line.

1. Wing stretcher

The wing stretcher module is intended for preliminary positioning and stretching of the bird’s wings allowing for a proper operation of the wing cutting module. Poultry is transported hanging in shackles, it’s breast facing forward. Two steel guides perform the stretching while the birds are moving through the machine. The module is easy to set up and adjust as it doesn’t have any moving parts.

2. Whole wing cutter

The whole wing cutter module consists of left and right cutting units symmetrically positioned in relation to the central line of the shackles. The two rotating blades are mounted on shafts and powered by electric motors. Chicken carcasses are transported to the module with their backs facing forward and are guided through the machine in flat-lying position. The wings are caught between guides and properly positioned by them. The wings cut by rotating blades fall into a container or onto a belt conveyor. Automation in this module significantly reduces labor costs and improves overall productivity.

3. Front half (tube) cutter

The front half cutter module that comes next easily removes the front half of the bird with wings and breasts from the back half with legs. This cut is performed by rotating blade with the bird moving sideways through steel guides. The front half falls down into a container or onto a belt conveyor. After the front half is removed, it can be further processed using cone deboning techniques for optimal meat extraction.

4. Adjustable saddle cutter

The adjustable saddle cutter module is intended for dividing of the remaining bird’s body into two or three parts. The backbone is separated from the left and right legs when the twin rotating blades are moved apart. The central part then falls down into a container or onto a belt conveyor. The blades can also be adjusted so that the back is divided into two parts through the centre of the spine.

5. Thigh-drumstick cutter

The thigh/drumstick cutter makes an anatomical cut through the joint and splits the thigh from the drumstick. The two legs are precisely positioned by a separating wheel before they are cut. The cut-off thigh falls down into a container or onto a belt conveyor while the drumsticks are transported to the next module. Further automation in this module ensures efficient management of tasks like wing cutting and dark meat deboning, adapting to market needs and maximizing yield performance.

6. Unloader

The unloader is a last module which unloads the remaining drumstick which in turn falls down into a container or onto a belt conveyor.

KEY FEATURES OF OUR CAROUSEL CUT-UP LINE

- Our Carousel Cut-up Line features a unique circular and open layout, allowing for easy access and maintenance. This design ensures that all components are easily accessible, making cleaning and upkeep straightforward and efficient.

- The compact design of the machine enables seamless integration with other systems and equipment in the poultry processing line. This flexibility allows for a more streamlined operation, enhancing overall production efficiency.

- The line is equipped with adjustable saddle cutter modules, ensuring consistent product quality and reducing human error. These modules can be fine-tuned to accommodate different sizes and types of poultry, guaranteeing precise cuts every time.

- The wing stretcher module and wing cutting module work in tandem to provide precise cutting technology and high-quality wing cuts. The wing stretcher positions and stretches the wings perfectly, allowing the wing cutting module to make clean, accurate cuts.

- The machine’s cutting units are symmetrically positioned, allowing for efficient and precise cutting of chicken carcasses. This symmetrical arrangement ensures that each cut is made with the highest level of accuracy, contributing to the overall quality of the final product.

- The Carousel Cut-up Line is designed for easy operation and maintenance, with a simple design and easy-to-use controls. This user-friendly approach minimizes the need for extensive training and reduces the likelihood of operational errors.

- The machine is capable of processing up to 2,500 birds per hour, making it an ideal solution for high-volume poultry processing facilities. This high capacity ensures that even the most demanding production schedules can be met with ease.

PRECISION CUTTING TECHNOLOGY

- Our Carousel Cut-up Line features advanced precision cutting technology, ensuring high-quality cuts and minimal waste. This technology is designed to deliver the best possible results, maximizing yield and minimizing product loss.

- The machine’s rotating blades are designed for precise cutting and are adjustable to accommodate different types of poultry products. This adjustability ensures that each cut is tailored to the specific requirements of the product being processed.

- The wing cutter module uses two rotating blades to provide accurate and efficient cutting of wings. These blades work together to make clean, precise cuts, ensuring that the wings are separated perfectly every time.

- The adjustable saddle cutter module allows for precise cutting of chicken carcasses into two or three parts. This module can be adjusted to make different types of cuts, providing flexibility and versatility in the processing line.

- The machine’s cutting technology is designed to minimize human error and ensure consistent product quality. By automating the cutting process, the machine reduces the risk of mistakes and ensures that each cut is made with the highest level of precision.

- The Carousel Cut-up Line is equipped with a separating wheel to precisely position the legs for cutting, ensuring accurate and efficient cutting. This wheel ensures that the legs are in the perfect position for cutting, resulting in clean, accurate cuts.

- The machine’s cutting technology is designed to optimize production efficiency and reduce waste. By making precise cuts and minimizing product loss, the machine helps to maximize yield and improve overall production efficiency.

ADVANTAGES

– Compact design, small dimensions

– Practically operatorless – only laborers for hanging chickens are required and all remaining actions are performed automatically

– Characterised by a simple design and is easy to install and operate. Compact design and circular and open layout make it easily accessible for maintenance and cleaning. It can be easily integrated with other systems when needed